Corporate Social Responsibility

INTRODUCTION

This report describes the policies and procedures that the Board has put in place to ensure that Aggreko operates in a safe, ethical and responsible manner, which protects the environment as well as safeguarding the health and safety of its employees, its customers, and the communities in which it operates. The process for identifying, evaluating and managing the risks that are considered significant is summarised under the heading of Internal Control within the Corporate Governance section.

The nature of our business is that we work in many different countries, often in remote and difficult environments, with equipment and substances which, if improperly handled, are potentially dangerous to people and harmful to property and the environment. We frequently operate in response to natural or manmade disasters, where the infrastructure has been badly damaged and where operating conditions are far from ideal. Over time, therefore, we have developed a comprehensive range of operating procedures and processes to ensure that we minimise any risk of harm to people or to the environment.

HEALTH AND SAFETY

Aggreko puts health and safety at the very heart of its operations. Most of our equipment is heavy, electromechanical equipment which is moved around frequently. Compressors and generators respectively produce high-pressure compressed air and high voltage electricity, either of which can be harmful to people if mishandled.

Aggreko's policy is to implement common health and safety operating procedures worldwide. Whether operating in the Australian bush, the Saudi Arabian desert or in downtown Manhattan, our operating procedures are the same high standard.

Among the key features of Aggreko's worldwide Health and Safety Policy are:

- ensuring that health and safety issues are at the forefront of considerations when we design our equipment;

- ensuring that our equipment is built and maintained to the highest standards;

- training and educating our staff worldwide in the safe operation of our equipment; and

- ensuring that health and safety issues have the appropriate level of focus throughout the management chain.

Aggreko has created its own Global Environmental Health and Safety Management System (GEMS) which has been implemented throughout the business. At the core of GEMS is a Best Operating Practice document that is published in ten languages. The Best Operating Practice is updated in the light of experience and incidents.

GEMS incorporates a comprehensive reporting system which is designed to ensure that the Company knows of every incident, and can learn from it. A uniform accident and incident data collection procedure is implemented worldwide, and from this we can measure our performance and benchmark our operations. Performance measures are reported at a business unit level on a monthly basis. Any serious incident is immediately reported to the Executive Director responsible for the business unit concerned.

Meetings of the senior management of each region are held regularly; at each of these an Executive Director will normally chair the meeting, and incidents reported under GEMS are discussed. Monthly Board reports are then produced on Health and Safety and considered at each meeting of the Board, along with a report from each of the Regional Executive Directors on Health and Safety in their particular region. The Executive Director with overall responsible for Health and Safety is Rupert Soames. In 2013, Rupert was supported in this role by George Walker (the Executive Director with responsibility for Health and Safety until 31 December 2012), going forward, Ron Sams (Group Manufacturing, Operations & Technology Director and a member of the Executive Committee), will have operational responsibility for coordinating Health and Safety policies and preparing reports to the Board.

SAFETY

Our business involves the frequent movement of heavy equipment which, in its operation, produces lethal voltages and contains thousands of litres of fuel. Rigorous safety processes are absolutely essential if we are to avoid accidents which could cause injury to people and damage to property and reputation. Safety processes are also a basic benchmark of operational discipline and there is, in our view, a close correlation between a well-run business and a safe business.

The main KPI we use to measure safety performance is the internationally recognised Frequency Accident Rating ('FAR') which is calculated as the number of lost time accidents multiplied by 200,000 (being the base for 100 employees working 40 hours per week, 50 weeks per year) divided by the total hours worked. A lost time accident is a work related injury/illness that results in an employee's inability to work the day after the initial injury/illness.

The Group's FAR for 2013 was 0.68. This compares favourably to the benchmark of 1.9 reported for US rental and leasing industries published by the US Department of Labor in 2012, and was an improvement on the 0.94 achieved in 2012.

Further discussion of Health & Safety matters can be found in this report in the Principal Risks and Uncertainties section and the Key Performance Indicators section.

FAR was as follows:

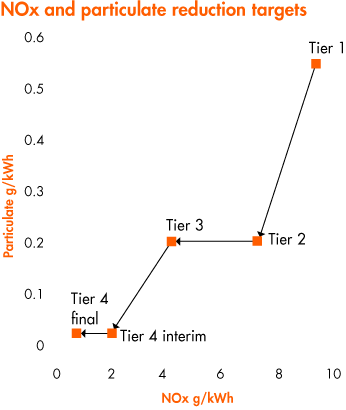

Year ended 31 December 2013 2012 2011 2010 2009 FAR 0.68 0.94 0.98 0.71 0.76 Set out below is an explanation of the terms and abbreviations used in this section. Aggreko's equipment is designed to function in all continents and all types of terrain. By careful design and use of the most suitable technology, we also aim to minimise the environmental impact of that equipment. Aggreko makes available to its customers equipment and solutions that are designed to comply with applicable laws, regulations and industry standards wherever we operate in the world. In effect, this means they comply with the laws, regulations and standards of some of the most stringent jurisdictions in which we operate and, therefore, far exceed the levels required in many others. The two major environmental issues we deal with in our business are emissions-to-air from our equipment – the majority of which is diesel powered with an increasing proportion of gas, and the safe handling and disposal of fuel and oil. Our Environmental Policies are managed in a similar way to safety. They comprise: Emissions-to-air are an inevitable by-product of hydrocarbon fuelled engines. Over the years, as engines have become more efficient and legislation to limit emissions around the world has become stricter, emissions have reduced sharply. Aggreko works in co-operation with the manufacturers of engines in order to meet new emission requirements in a timely manner. The principal contribution we can make to reducing emissions to air is in maintaining our equipment in good order, and introducing engines into the fleet with good emissions performance. In an increasing number of countries, air quality regulations stipulate emission standards with which new equipment being sold must comply. Generally countries allow mobile equipment already operating to continue to do so for its useful life. This is called 'grandfathering'. The US EPA has introduced the earliest and most stringent regulation in this area, introducing reduction targets for emissions of NOx and particulate in Tiers, starting with Tier 1 in 1996, moving to Tier 4 final in 2014. The EPA requirements have therefore been the main driver of new generator development. The following graph illustrates the reduction targets for emissions under the EPA regime. As our suppliers produce engines which comply with new emissions, we work with them to introduce the new engines into the fleet. In 2008, we started trialling new Tier 2 compliant engines for our highhorsepower range, and these were introduced into production in 2010. During 2011 and 2012 we continued our investment in new emissionised fleet and by the end of 2012, the vast majority of our North American power fleet was certified to operate at Tier 2 EPA standards or above. During 2013, around 25% of the new diesel engines introduced to our worldwide fleet were certified to at least Tier 3 in North America or the equivalent Stage 3A standard in Europe. At the same time, we continued our investment in Tier 4 Interim products, launching three new models in 2013. Over 15% of the new diesel engines introduced to our worldwide fleet in 2013 were certified to the Tier 4 Interim standard. We expect this trend for increasing emissions compliance to continue and we will continue to introduce new Tier 4 Interim certified products. Research and planning for Tier 4 final, for our classification of use, is underway and we expect that there will be solutions and product available in 2015. To further reduce emissions-to-air for specific projects, after-treatment can be applied to existing fleet. In 2008 a significant project was undertaken in Chile to deliver the lowest level of NOx yet stipulated by a standard. Seventy of Aggreko's project machines were fitted with an advanced SCR unit that reduced NOx by 90%. More recently the post Tsunami diesel projects, totalling 248MW, utilised this technology on Aggreko machines to meet the Japanese air quality standards. Similar technology will be required to meet EPA Tier 4 final requirements in the US and in Europe thereafter. We are currently working closely with engine manufacturers and primary technology developers to derive appropriate solutions for these requirements. For the 2012 London Olympics, we developed and deployed a retrofit solution for existing fleet to meet LOCOG's stringent demands for low emission levels. We are constantly exploring new ways of reducing emissions, and have now built up a fleet of 1,485MW of gas-fuelled equipment, comprising 1MW sets used in our Power Projects and Local business as well as smaller gas-fuelled generators used in the Local business. This temporary power solution has significantly lower levels of emissions (see below). In 2013, over 14% of the new generator sets manufactured and introduced to our worldwide fleet were gas powered. Tier 1 engine Gas engine Reduction NOx 8.5 g/kWh 1.4 g/kWh 74% Particulates 0.10 g/kWh 0.04 g/kWh 60% CO2 intensity 669 g CO2/kWh 520 g CO2/kWh 22% Natural gas presents a competitive advantage over other energy sources. It is seen as economically more efficient because only about 10% of the natural gas produced is wasted before it gets to final consumption. In addition, technological advances are constantly improving efficiencies in extraction, transportation and storage techniques as well as in equipment that uses natural gas. Natural gas is considered an environmentally-friendly clean fuel, offering important environmental benefits when compared with other fossil fuels. The superior environmental qualities over coal or oil are that emissions of sulphur dioxide are negligible and that the level of NOx and CO2 emissions is significantly lower. Where the gas fuel is essentially a by-product of production or is derived from a biological source, a CO2 and greenhouse gas reduction is realised. This helps to reduce problems of acid rain, ozone or greenhouse gases. In many of Aggreko's target markets natural gas is effectively a stranded resource. Aggreko's service allows for generation of power from this valuable resource on a more flexible and scalable basis than existing solutions. In addition to the work we have undertaken developing natural gas-powered generators, we are constantly reviewing product technologies, looking for advances that we can adopt within our product portfolio. These include: Aggreko Greenhouse Gas Emissions Report 2012 and 2013 However, over the past few years the pressure from various bodies to give a single number has mounted, and this year became a requirement. Last year for the first time we employed a consultant to estimate what our GHG emissions are, and we've used them again this year. Accordingly, this report presents our scope 1, 2 and 3 GHG emissions for the calendar years 2012 and 2013. In order to calculate the GHG emissions, we have used the method outlined in the GHG Protocol Corporate Accounting and Reporting Standard (revised edition), together with the latest emission factors from recognised public sources including, but not limited to, Defra, the International Energy Agency, the US Energy Information Administration, the US Environmental Protection Agency and the Intergovernmental panel on Climate Change. Tables 1 and 2 below present the principal findings from GHG analyses of the previous two years. Table 1: Total GHG emissions by GHG protocol scope tCO2e/year* 2012 2013 Scope 1 12,639,771 16,287,898 Scope 2 14,168 14,554 Scope 3 2,358,459 3,071,360 Total 15,012,398 19,373,812 *tCO2e/year defined as tonnes of carbon dioxide equivalent. Table 2: Total GHG emissions by fleet/non-fleet tCO2e/year 2012 2013 Fleet 14,850,161 19,225,517 Non-fleet 162,237 148,295 Total 15,012,398 19,373,812 The results show that 99% of GHG emissions arise from customers' operation of our rental fleet. In line with best practice, our GHG accounting systems include an estimate of the upstream GHG emissions associated with fuel supply chains which typically add 18.5% to combustion emissions; this 18.5% accounts for 98% of the scope 3 emissions detailed in Table 1. Given the dominance of fleet emissions, there are three main factors driving Aggreko's total annual GHG emissions: the fuel type our customers chose to use; the pattern of their usage; and the fuel efficiency of Fleet. Only the last of these is under the control of Aggreko. The increase in GHG emissions between 2012 and 2013 largely reflects the increase in fuel used by our customers, where total energy delivered has increased by over 31%. The fact that the increase in total GHG emissions was 29% demonstrates a decrease in the underlying carbon intensity of our fleet, mainly due to a slight proportionate increase in our gas fleet. Without the fleet carbon intensity reduction of 2% between 2012 and 2013, the total GHG emissions in 2013 would have been approximately 290,000 tonnes CO2e higher. Our investment in new fleet has therefore reduced GHG emissions by just over one quarter of a million tonnes in a year, almost double Aggreko's non-fleet emissions. In addition to reporting our GHG emissions, we are also now required to report a net intensity metric as appropriate for Aggreko. Intensity ratios express the GHG impact per unit of physical activity or unit of economic output; a declining intensity ratio reflects a positive performance improvement. Having given this some consideration, and as the majority of the GHG emissions we report are generated by customers operating our fleet, we have chosen Revenue Intensity as the most suitable metric for our business. Our intensity metric is therefore an indication of emissions per £1 of Revenue generated and is presented in Table 3 below: Table 3: Revenue intensity ratio tCO2e/£ 2012 2013 Revenue intensity ratio 9.5 12.3 Whilst on the face of it our revenue intensity ratio appears to have worsened over the year, this masks the underlying performance in our business. In 2012, a lot of our equipment was on-hire but was not running; it was in fact on standby. The way our Power Projects contracts works is that we are paid a capacity charge to provide the equipment even if it doesn't run; in which case we have revenue without emissions. When the equipment runs, which more of it did in 2013 with a 17% increase in running hours, we acquire incremental revenue but we also produce emissions. Given that about 75% of the average contract cost is the capacity charge, the revenue intensity ratio is heavily geared and therefore significantly impacted when our equipment runs. There are some more general points we should make: first, Aggreko is committed to growing its business and if we are successful it is inevitable that the amount of fuel our customers burn, and therefore the amount of GHG emissions from our generators, will increase. However, by investing in alternative fuels such as gas and fuel-efficient engines, we can seek to mitigate the impact of growth. Second, whilst diesel-powered generation is viewed by many environmentalists as the devil's spawn, a significant amount of our capacity is dedicated to making practical emissions-free generation such as hydro, practical. Like all sources of renewable energy, hydro is intermittent, i.e. when it does not rain, you get no hydro power. In many parts of Africa, South America and Asia the rains fail every 4-6 years, and they need alternative generation to support the grid when this happens. Supporting hydro with diesel is a core part of our business, and enables these countries to provide both low-emissions generation and continuous supplies of electricity, even in times of drought. Thirdly, legislation over the last twenty years related to combustion engines has focussed on reducing emissions such as Nitrogen and Sulphur Dioxide, which are just as harmful as CO2. Engine manufacturers have been very successful at this, but, perversely, lower nitrogen and sulphur dioxide emissions come at the cost of worse fuel consumption, and therefore more CO2. So as our fleet gets cleaner by one measure, it gets dirtier by another. Aggreko and its customers handle a considerable quantity of diesel fuel and the rare occurrence of accidental fuel spills is an area that the Group monitors very closely. The measure used by management to measure the performance of the Group in handling fuel is the 'Petroleum Release Rating' (PRR). This is calculated as litres released to ground, divided by the cumulative average MW on rent. The PRR performance over the past three years has been: Our equipment has been specifically designed to minimise the risk of fluid spillage through features such as a 'save-all base', double-walled storage tanks and fail-safe valves. A PRR score of 0.35 has been set by the Group as a target for 2014, based on 90% of the actual performance for 2013. Another potential source of environmental damage is in the disposal of consumables such as engine oil and filters. In our Local business, these are normally returned to our service centres where they are safely disposed of. In our Power Projects business, sitespecific arrangements are made to ensure the safe handling of these items. Reporting of fuel spills is handled in a similar way to safety incidents, with monthly reports reviewed at each meeting of the Board. Aggreko has built a competitive advantage through an equipment fleet that minimises external noise. This is done by the use of custom-built acoustic enclosures as well as high performance isolation and attenuation systems. Aggreko continues to work closely with its suppliers and local university research departments in order to develop its expertise in this field. As a result, our equipment is able to achieve the following performance standards that are well below the maximum levels permitted by current European legislation. Size of generator Certified noise level (Sound Power LWA) Prime power Maximum EU limit Aggreko Standard Product Aggreko Premium Product 30kVA 96.47 92.0 78.0 60kVA 96.77 93.0 80.0 125kVA 97.10 94.0 83.0 200kVA 97.30 94.0 91.0 350kVA 97.55 92.0 90.0 Note: A reduction of 3 LWA in the certified noise level equates to an audible noise level that is approximately 50% lower. In accordance with the timelines and accords set out by the Montreal protocol Aggreko has phased out CFC plant from its temperature control rental fleet and is in the process of phasing out HCFC plant; we have introduced HFC production models in all areas. Aggreko is committed to promoting equal opportunities for all, irrespective of disability, ethnic origin, gender or any other considerations that do not affect a person's ability to perform their job. The Group's policies for recruitment, training, career development and promotion of employees are based on the suitability of the individual and give those who are disabled equal treatment with the able bodied. Where appropriate, employees disabled after joining the Group are given suitable training for alternative employment with the Group or elsewhere. The Group continues to operate team briefings throughout its business to keep employees informed of developments and plans, both in their own operations and in the Group as a whole. Employees have access to the 'Aggreko Resource Centre', an intranet based system, which provides them with a wide range of information on the activities of the Group around the world. The annual and interim results are publicised extensively throughout the business and are made available to all employees. The Group has an externally facilitated whistleblowing hotline, which gives access for all employees to a confidential, multi-lingual service to report any cases of ethical non-compliance, bullying or discrimination. The table below shows the breakdown by gender at different levels within the organisation. We have included the information below on Subsidiary Directors as this is required by the Companies Act 2006 (Strategic Report and Directors' Reports) Regulations 2013 however we believe that a better reflection of Senior Management would be those employees who are the main direct reports to the Executive Directors, that is, the other members of the Executive Committee, the members of the three Regional Management Teams and the two key central financial appointments of Director of Finance and Group Treasurer. Year end 31 December 2013 Male Female Total % % PLC Board 10 2 12 83% 17% Senior Management (Executive Director main reports) 34 4 38 89% 11% Senior Management (Subsidiary Directors) 68 3 72 96% 4% Whole Group 4,956 982 5,938 83% 17% At Aggreko we have always taken our responsibilities to individuals seriously, whether they are our employees or other people who might be affected by our operations. We have identified matters such as Safety, Emissions, and People as matters to be considered as part of the principal risks and uncertainties facing the business, and we have explained our approach to Health and Safety, Equal Opportunities, emissions and noise (in the section on The Environment) and grievance mechanisms (see the description of our whistleblower hotline). Whilst all these matters are linked, to a greater or lesser extent, to human rights, we prefer to address them as part of our operations, rather than as a separate issue of human rights, and although we continue to evaluate all potential risks, we do not think that human rights otherwise present material issues for our business. Aggreko has a policy of encouraging local teams to engage with the communities in which they work, and each year they undertake a number of initiatives to help the disadvantaged or those affected by natural disasters. During 2013, the Group contributed to a range of charitable, community and disaster relief organisations. We have a policy of giving little donations to many organisations which are involved with the communities in which we work, rather than giving a lot of money to a few. Our largest single donation goes to Book Aid International, a charity promoting literacy in Africa with whom we have been working since 2006. Book Aid has provided hundreds of thousands of books to schools and libraries. We admire their work enormously, and donations from Aggreko have enabled books to be distributed in Cameroon, Kenya, Namibia, Tanzania and Uganda. Books are, we feel, a good form of donation; they do not require maintenance; they can be used by many people; they are not open to corruption; they last a long time; and they help directly in the key task of helping people to help themselves. Aggreko has a reputation for delivering innovation, performance and solutions. Also at the heart of our long-term success is something less tangible and less easily illustrated with figures or case studies. This key element is integrity and honesty in our business dealings, a factor that contributes to our long-term relationships with customers. All Aggreko employees, as well as consultants and agents who we work with, are expected to behave ethically in their work, and our expectations of them are set out in a Corporate Ethics Policy. The objective of the Policy is to make Aggreko a good company to work for; to maintain our reputation for exceptional customer service and ethical business dealings; to compete ethically; and to ensure the business is managed to a consistently high standard. The Board has an Ethics Committee comprising Ken Hanna (Chairman), David Hamill and Diana Layfield, to oversee the implementation of the Group's policies and procedures set out in the report of the Committee. Further discussion of our policies for handling ethical risks is set out under Principal Risks and Uncertainties – Failure to conduct business dealings with integrity and honesty. Employees who suspect any breaches of the Corporate Ethics Policy are encouraged to speak up, and their confidentiality and position is protected if they do so. Our Group-wide whistleblowing hotline, described, helps this process. Further information and copies of the Environmental, Health and Safety Policy and Corporate Ethics Policy are available at http://ir.aggreko.com/investors/corporate-responsibility.

THE ENVIRONMENT

Environmental policy

Emissions-to-air: exhaust gases and particulates

Aggreko natural gas generator development

Alternative energy sources

Emissions-to-air: carbon dioxide

We are somewhat sceptical of the reporting on greenhouse gas (GHG) emissions. Our issue is not with the principle of reporting, it is with attempting to impose spurious levels of accuracy and pretending that the numbers produced are accurate. They are not: they are an aggregate of many hundreds of more or less wild guesses. By way of example, in our reporting, 84% of our GHG emissions comes from our customers burning fuel in our engines. But 'best practice' dictates that we add 18.5% to this number to 'account for' the assumed GHG gases expended making the fuel and getting it to site, irrespective of whether fuel gets to our engine down a pipeline or in a truck. This 18.5% dwarfs our own in-house emissions.

Petroleum spills and the safe disposal of waste fluids

Noise

Refrigerant

EMPLOYEES AND EQUAL OPPORTUNITIES

DIVERSITY

male

female

HUMAN RIGHTS

OUR WORK IN THE COMMUNITY

Policy

Charitable donations

BUSINESS ETHICS

Ethics Policy

SEE OUR CORPORATE RESPONSIBILITY WEBSITE

![]()

Rupert Soames

Chief Executive

6 March 2014

Angus Cockburn

Chief Financial Officer